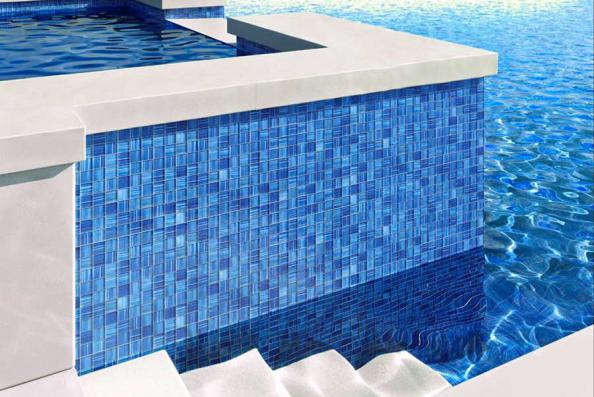

Pool ceramic tiles are one of the products that is very important in the construction industry and building beautification and is used for sanitary purposes and decoration inside or outside the building and waterproofing. One of the places where tiles are used is in buildings, swimming pools and Jacuzzis. Pool tiles are offered in various dimensions, designs and prices which differ from ordinary tiles in the amount of water penetration in them.

Using 4 Types of Ceramic Tiles to Construct Pool

The use of pool vintage ceramic tiles is more suitable for indoor environments, because it is less resistant to environmental pressures such as temperature changes than ceramics, so it is more used in walls. Ceramic tile types can be used as a floor covering due to its higher pressure tolerance, but it has less variety of designs and colors than tiles. These ceramics have a glossy glaze and this factor makes the pool or jacuzzi environment look bigger than it is. As mentioned, the price of the tiles depends on the dimensions and quality as well as the type of design used in them. Pool tiles are more expensive than regular tiles due to their higher quality and different properties than ordinary tiles.

Use of pool tiles are divided into general types of simple pool tiles, miniature, rectangular, checkered, and three-dimensional, which themselves have subcategories. Iran is one of the best suppliers of ceramic tiles, offering all kinds of these pool tiles. Although these xeramic tile quality are produced and supplied in various dimensions, but for pools, it is recommended to use tiles with a smaller size, because this reduces the possibility of slipping in the pool. If we pour water on the back of these tiles, we will see that water does not penetrate into them, while if we do the same with ordinary tiles, we will see water penetrating. Pool tiles are also resistant to frost.

How to Recognize the Grades of Ceramic Tiles?

Tiles are graded according to specific definitions into four categories: first grade, second grade, third grade and fourth grade, which indicates the quality, quality and amount of defects in the product. The quality of ceramic tiles is tested in laboratories located on the factory site or outside. In these laboratories, the dimensions, thickness and strength of ceramic tiles as well as other important factors are examined.

The degree of ceramic is very important and should be considered. Usually, the degree of manufacture of ceramics and other information is recorded on the carton with the help of a jet printer or other equipment, the degree of which can be determined by referring to the carton of each ceramic. Ceramics of quality four are usually packed in white cartons. The information recorded on the carton includes the date of manufacture, grade and manufacturing code, and these numbers are entered linearly on the carton; In some cases, they are placed on the carton in the table and its degree can be easily checked. But in cases where we do not have access to the carton, its degree can be determined according to the quality of the ceramic glaze and the absence of stains in the ceramic.

How to Recognize the Grades of Ceramic Tiles?

Ceramic grade is a criterion that indicates the accuracy and quality of ceramic construction. First-class ceramics are made of high quality materials that have high strength and durability and have good stability against external forces and factors. Another point that is considered about the degree of construction of a ceramic is always its dimensions that first-class ceramics are completely similar and have a small amount of tolerance or difference. The use of first-class ceramics makes the space more beautiful, and also the implementation of this type of ceramics for the architect who is responsible for doing this, is done with less effort and ends in less time; Because there is no need to align the ceramics and they can be easily placed together without any differences.

Your comment submitted.